Main places of application:

- Ferrous and nonferrous metallurgy, mining and enrichment plants

- Construction, dismantling (demolition) of buildings and structures

- Pits and mines

- Sea, river and railway cargo terminals

- Production of building materials (gypsum, cement, concrete)

- Operating and recultivated solid waste landfills

The main ways to create water mist

High pressure fog. Water spraying at a pressure of 60–120 bar through nozzles with a hole of 0.2–0.5 mm. The pressure in the working line is created by plunger (piston) pumps. The particle size of high-pressure mist is from 2 to 60 microns, the average is 10–30 microns. With this method, no compressor station is needed to produce compressed air, but a pump station and high-pressure pipes are required. Also the requirements for water quality are higher — multistage and water softening are often required. This method of suppressing dust does not work at low temperatures.

Water-air mist. Water spraying at a pressure of 1–5 bar using compressed air at a pressure of 5–8 bar through two-phase water-air nozzles. Nozzles can be with internal and external mixing. Two-phase nozzles are less demanding on water quality, can work at negative temperatures, certain nozzle types can operate at an ambient temperature up to –20 ... 30 ° C, as water particles of less than 20 microns do not freeze at such temperatures.

Creating a complete dust suppression system may require an expensive compressor station, heating system, and drainage (drainage, air blow) of pipelines.

The main types of two-phase water-injectors:

- 80° angle, water 7 l/h at 1,2 bar, air 115 l/min at 5,2 bar, fog particle of 3–6 µm

- 30° angle, water 45 l/h at 0,6 bar, air 260 l/min at 3,5 bar, fog particle of 4–10 µm

- 60° angle, water 20 l/h at 1,2 bar, air 240 l/min at 5,2 bar, fog particle of 7–10 µm

Mist (aerosol) cannons. Water spraying at 5-40 bar pressure through nozzles using powerful fans (turbines). The pressure in the working line is normally created by multistage pumps. The particle size of this fog is from 50 to 250 microns. Guns can be equipped with valves for blowing the line, heating units for nozzles and pipes, remote controls, multifunctional PLCs. The main versions are on a steel platform, on a wheeled trailer, on a truck chassis, on a steel column or mast, on a hydraulic mast with variable height.

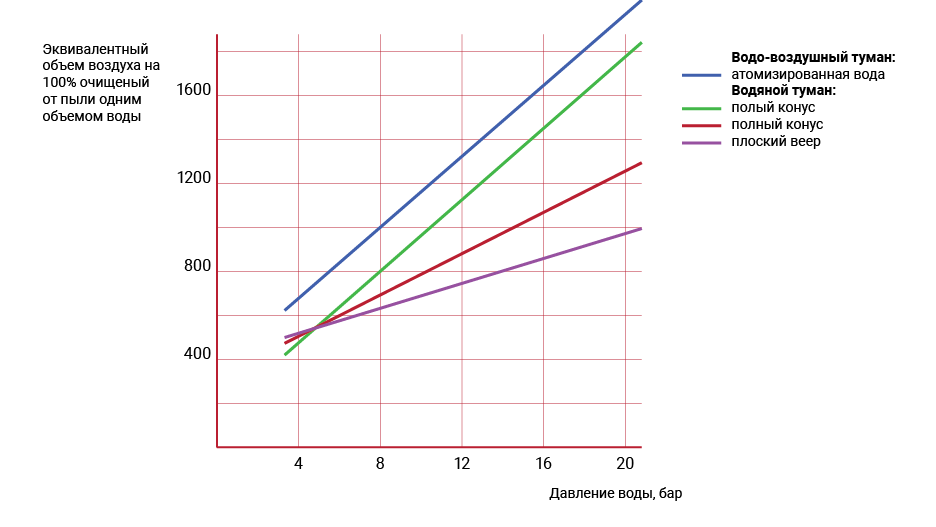

Comparison of spraying efficiency

Fog droplet sizes

Water dust suppression systems based on low and medium pressure nozzles without using compressed air create a mist consisting of too large drops of water. In order for such a mist to bind dust, expensive surfactants must be added to it, or a lot of mist must be created, which can cause overmoistening of materials and increased water consumption.

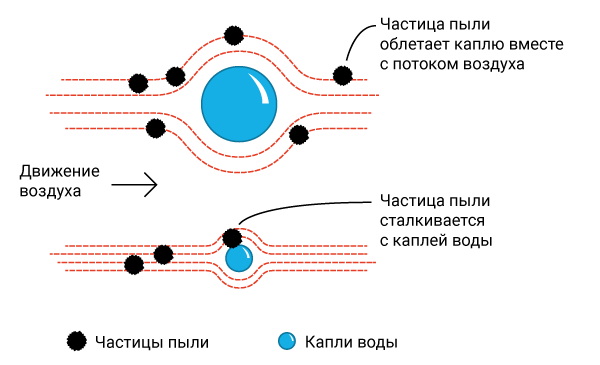

Water-air or high-pressure systems are capable of creating water particles, the size of which, from 2 to 30 microns, depending on the type of nozzle and working pressure, can successfully bind dust particles of different types due to the commensurability of sizes.

Fine or ultrafine mist does not make the material wet, consumes a small amount of water relative to the amount of dust or dusty material. Simplified consumption is 1 liter of water per 1 ton of material.